Precious metals are highly valuable assets, making their secure storage and accurate inventory management critical for businesses and investors alike. In this comprehensive guide, we explore the best practices for conducting precious metal storage inventory audits, ensuring transparency, security, and compliance. From preparation to执行and reporting, learn how to maintain the integrity of your precious metal holdings.

The Foundation of Precious Metal Storage Inventory Audits

Precious metals, including gold, silver, platinum, and palladium, are among the most sought-after assets in the global market. Their storage and inventory management require meticulous attention to detail, as even a small discrepancy can lead to significant financial losses or legal complications. Conducting regular inventory audits is a cornerstone of effective precious metal storage management, ensuring that the recorded quantities match the actual holdings.

Why Inventory Audits Are Essential

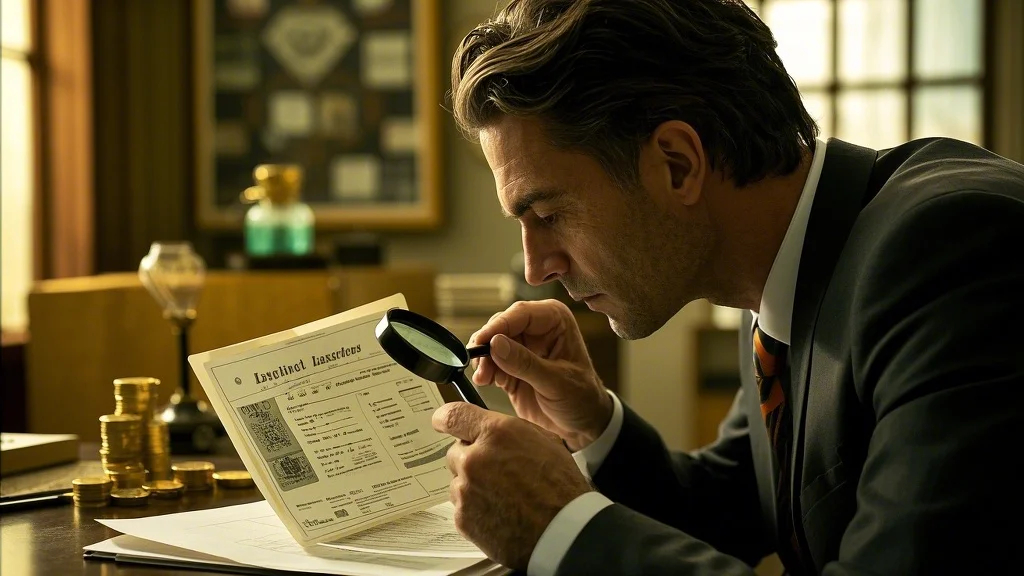

Inventory audits are not just a formality; they are a critical component of risk mitigation. By verifying the actual stock against recorded data, businesses can identify discrepancies early, address theft, fraud, or errors, and ensure compliance with regulatory requirements. Precious metals are often stored in secure facilities, but human error, technical glitches, or malicious activities can still lead to inaccuracies. Regular audits act as a safeguard, providing peace of mind and reinforcing trust with stakeholders.

Best Practices for Audit Preparation

Before conducting an inventory audit, proper planning is essential. Here are some key steps to ensure a smooth and effective process:

Define the Scope

Clearly outline the objectives of the audit, including the types of metals, storage locations, and the timeframe to be covered. This ensures that the audit is focused and comprehensive.

Gather Documentation

Pull together all relevant records, such as purchase receipts, invoices, and previous audit reports. Digital records should be cross-referenced with physical documents to eliminate discrepancies.

**Select a Qualified Audit Team

An audit team should consist of experienced professionals who understand the complexities of precious metal storage. If internal resources are limited, consider hiring external auditors with expertise in the field.

Schedule the Audit

Coordinate with storage facilities and stakeholders to choose a convenient time for the audit, minimizing disruptions to operations.

Conducting the Audit

The core of the audit lies in verifying the actual inventory against recorded data. This involves several key steps:

Physical Counting

The most critical aspect of an audit is the physical count of precious metals. Each piece should be meticulously examined, and its weight and purity verified. For larger holdings, counting should be done in smaller, manageable batches to reduce the risk of errors.

**Use of Technology

Modern technologies, such as barcode scanning, RFID tags, and automated systems, can streamline the audit process and reduce the likelihood of errors. These tools are particularly useful for tracking high-value items and ensuring accurate data collection.

**Verification of Assay Reports

Precious metals are often assayed to determine their purity and weight. During the audit, it’s essential to verify that the assay reports match the stored metals and that no tampering has occurred.

**Spot Checks and Sampling

To ensure the integrity of the audit, conduct random spot checks and sampling of the inventory. This helps identify any anomalies or inconsistencies that may have been missed during the initial count.

**Review of Storage Conditions

Precious metals require specific storage conditions to maintain their value and integrity. As part of the audit, review the storage environment for factors such as humidity, temperature, and security measures that could impact the metals’ condition.

Maintaining Records and Reporting

After completing the audit, it’s crucial to document the findings accurately. Develop a detailed report that outlines any discrepancies, their potential causes, and recommendations for improvement. Share this report with relevant stakeholders, including senior management and regulatory bodies, to ensure transparency and accountability.

Enhancing Inventory Audit Practices

While the foundational practices of inventory auditing are essential, there are additional steps businesses can take to elevate their audit processes. By adopting advanced strategies and leveraging technological advancements, organizations can achieve greater precision, efficiency, and security in their precious metal storage inventory audits.

1. Implementing Robust Security Measures

Security is a top priority when it comes to precious metal storage. To enhance audit practices, businesses should invest in state-of-the-art security systems, including biometric access controls, surveillance cameras, and alarm systems. These measures not only protect against theft but also provide an additional layer of security during the audit process.

2. Leveraging Technology for Real-Time Inventory Management

Advancements in technology have made it possible to monitor inventory in real-time. By integrating systems like IoT-enabled sensors and blockchain technology, businesses can track the movements and status of precious metals with unparalleled accuracy. Real-time data not only streamlines the audit process but also reduces the risk of errors and fraud.

3. Establishing a Culture of Continuous Improvement

Inventory audits should not be a one-time exercise but a continuous process. By establishing a culture of continuous improvement, businesses can identify and address issues before they escalate. Regular training programs for staff, periodic updates to audit protocols, and ongoing evaluation of storage facilities are essential components of this approach.

4. Addressing Common Challenges

Conducting precious metal storage inventory audits comes with its own set of challenges, including human error, technological limitations, and external threats. To overcome these challenges, businesses should:

Implement Regular Training: Ensure that all staff involved in storage and auditing processes receive regular training on best practices and technological tools.

Invest in Reliable Technology: Choose technologies that are scalable, secure, and user-friendly to minimize the risk of errors.

Conduct Risk Assessments: Regularly evaluate potential risks, such as theft or fraud, and implement measures to mitigate them.

5. Fostering Collaboration with Stakeholders

Precious metal storage and inventory management often involve multiple stakeholders, including suppliers, custodians, and regulatory bodies. Effective collaboration with these stakeholders is crucial for ensuring the success of inventory audits. Businesses should maintain open lines of communication, share best practices, and work together to establish industry standards.

6. Embracing Future Trends in Asset Management

The world of precious metal storage is constantly evolving, with new trends and technologies emerging. By staying ahead of these trends, businesses can ensure that their audit practices remain efficient